Biggest Supply Chain Pain Points Today

In today's supply chain process, business operations require more flexibility with innovative business solutions to scale up their operations which requires real time information and intelligence

Forward-looking Visibility

Deviations in the supply chain process, the exceptions are not to be seen far enough in advance to correct the root cause in many supply chain planning process.

Network-wide Transperancy

Supply Chain partners in the extended supply chain have blind spots. A small deviations from plan at one end of the supply chain have large and costly effects up and down stream which is known as bullwhip effect.

Reactive Management

The late notifications and identification of unplanned events drives reactive management of likely impacts. Planners loose productive time tending to low value adding exceptions leading customers to substitute brands or make purchases from competitor.

Demand Uncertainty

The uncertainty in demand leads to excess inventory and the uncertainty in supply leads to speculative ordering. It creates deployment issues in determining where, and what quantity of inventory to deploy in the network, across dimensions of time, geography and demographics.

Sub-optimal Plan

The lack of planning into stock levels up and downstream leads to shortages followed by overcompensation & excesses. Sometime this leads to increased level of discounting or write-offs for slow-moving or obsolete inventory.

Data Availability

Critical and vital information is not available when needed resulting in lost sales, out-of-stocks and unnecessary mark downs and reduction.

Touchless-AI for your Supply Chain Planners

SCAI augments your planners' intelligence by equipping them with information to ensure right product-mixx in right quantity at right place & at right time

AI Automation

AI enabled Automation for model selection, prediction & optimization

Integration

Application seam-lessly integrates with your underlying ERP system

Collaboration

Planners work with each other to take remedial actions on exceptions

Explainable AI

Planners get causal factors behind predictions to make informed decisions

Value Reporting

Tracks how much value application is helping you save through actions

4 Week Configuration

Modular design to speed up application delivery for your Enterprise

Want more? You're in the right place!

More to Discover

We waited until we could do it right. Then we did! Instead of creating a carbon copy of traditional ERP systems, we built a system of cognition for modern-day Supply Chain.

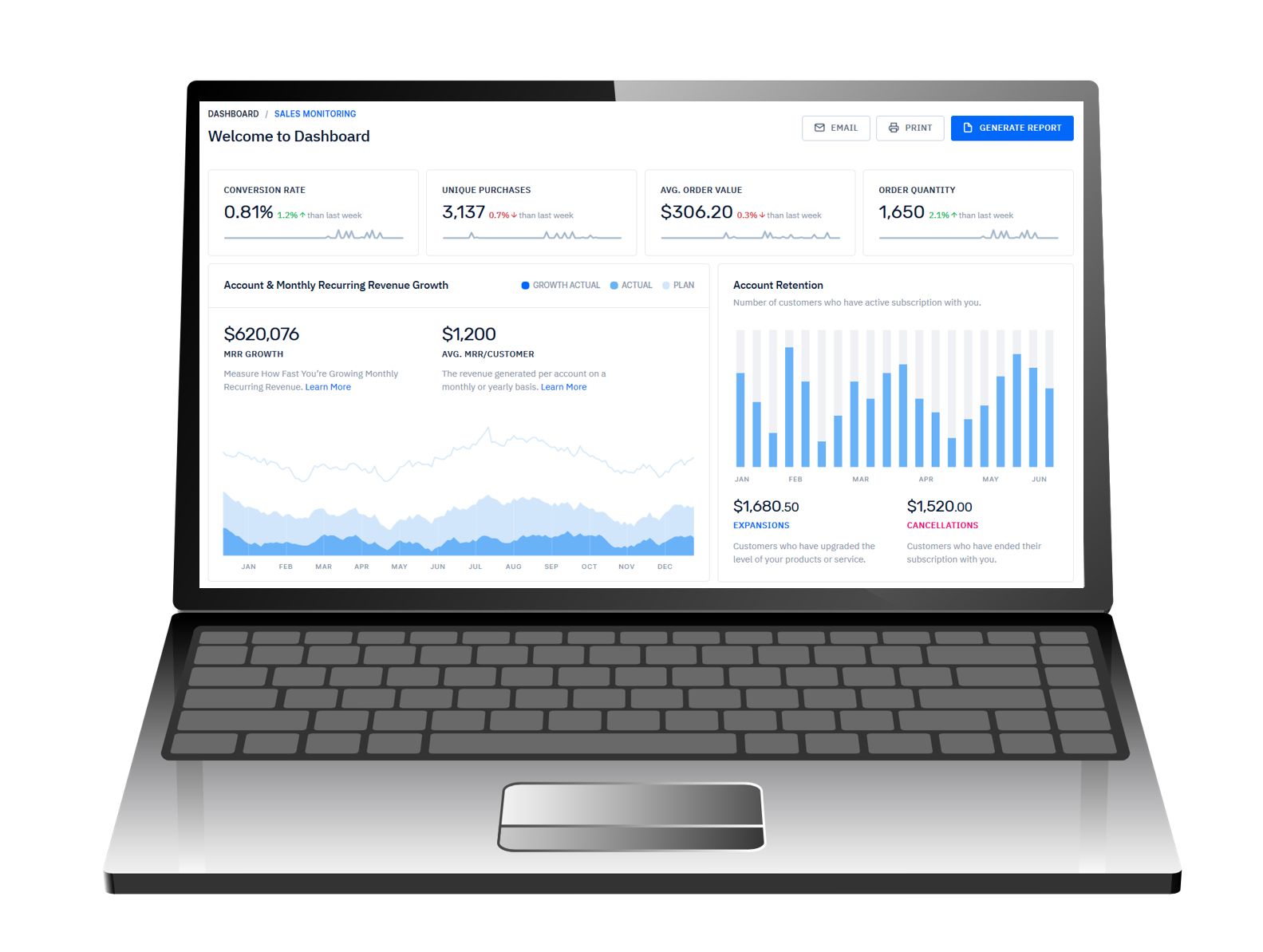

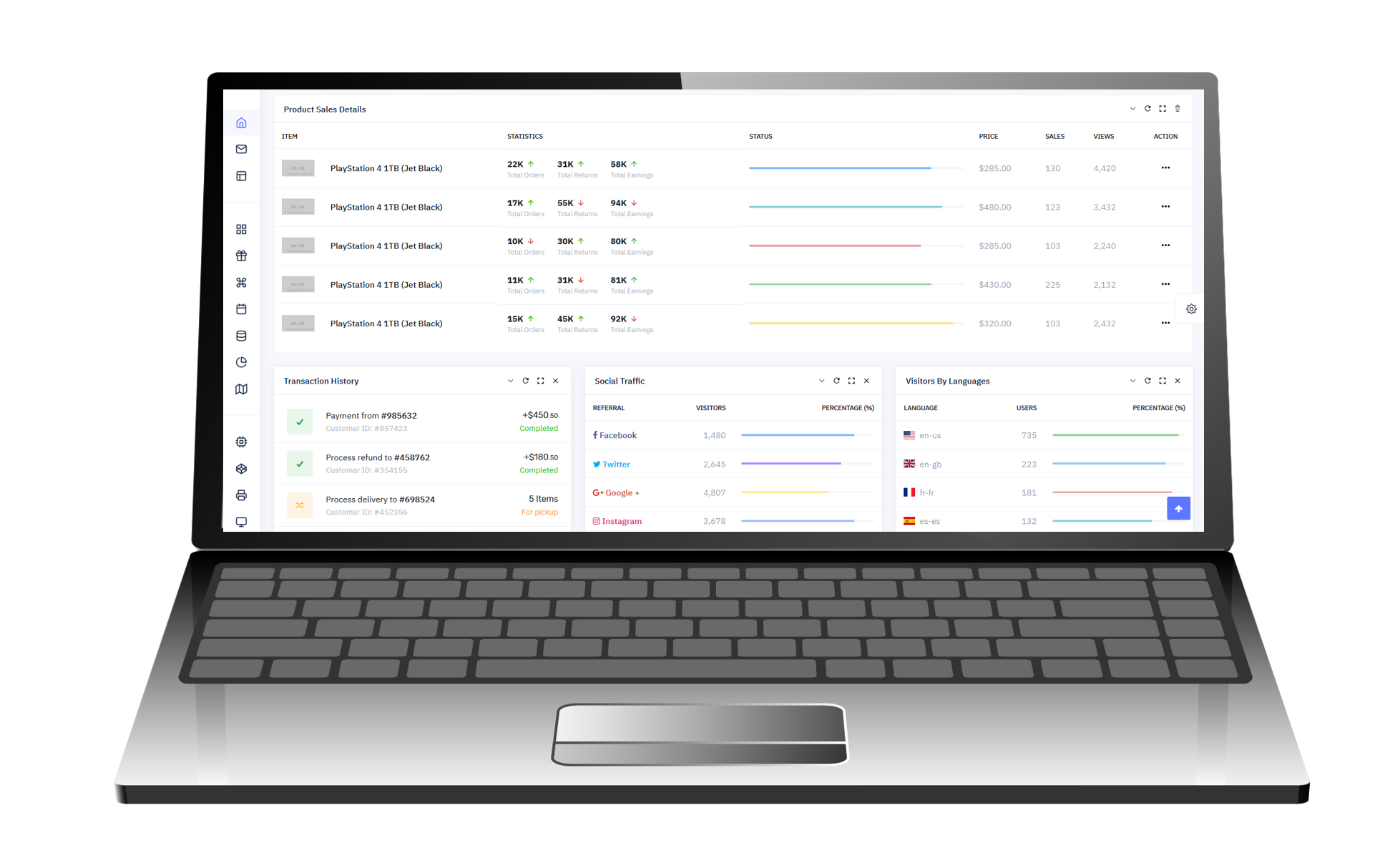

Monitor your Supply Chain

Monitor module gives planner high level insights on:

- Stressed out Product Categories

- Regions & Locations with imbalances

- Forward looking potential value leakages

- Magnitude of $ Value Leakage by Products, Categories, Regions & Nodes

- In nutshell, planner gets areas to focus to plug value leakages

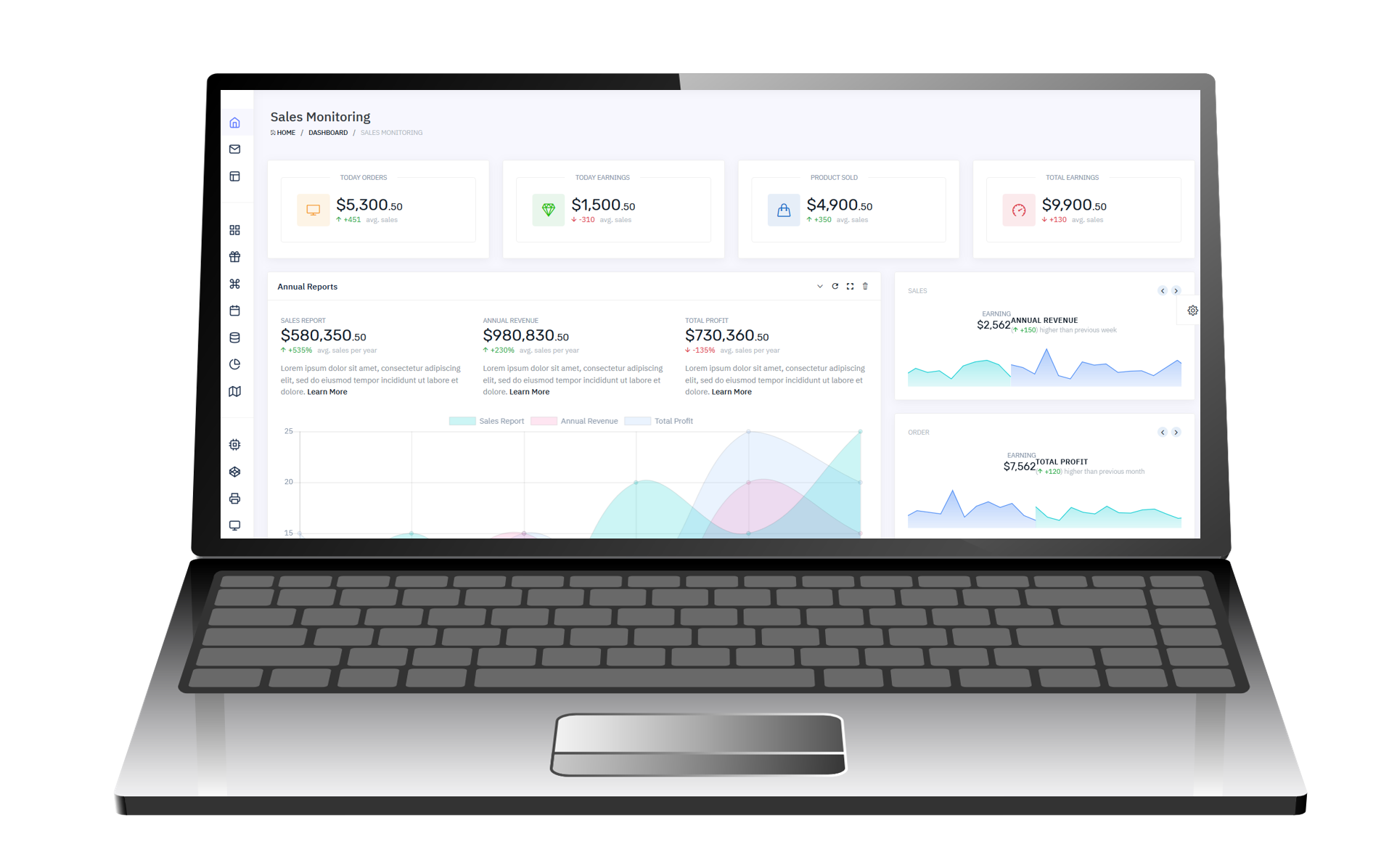

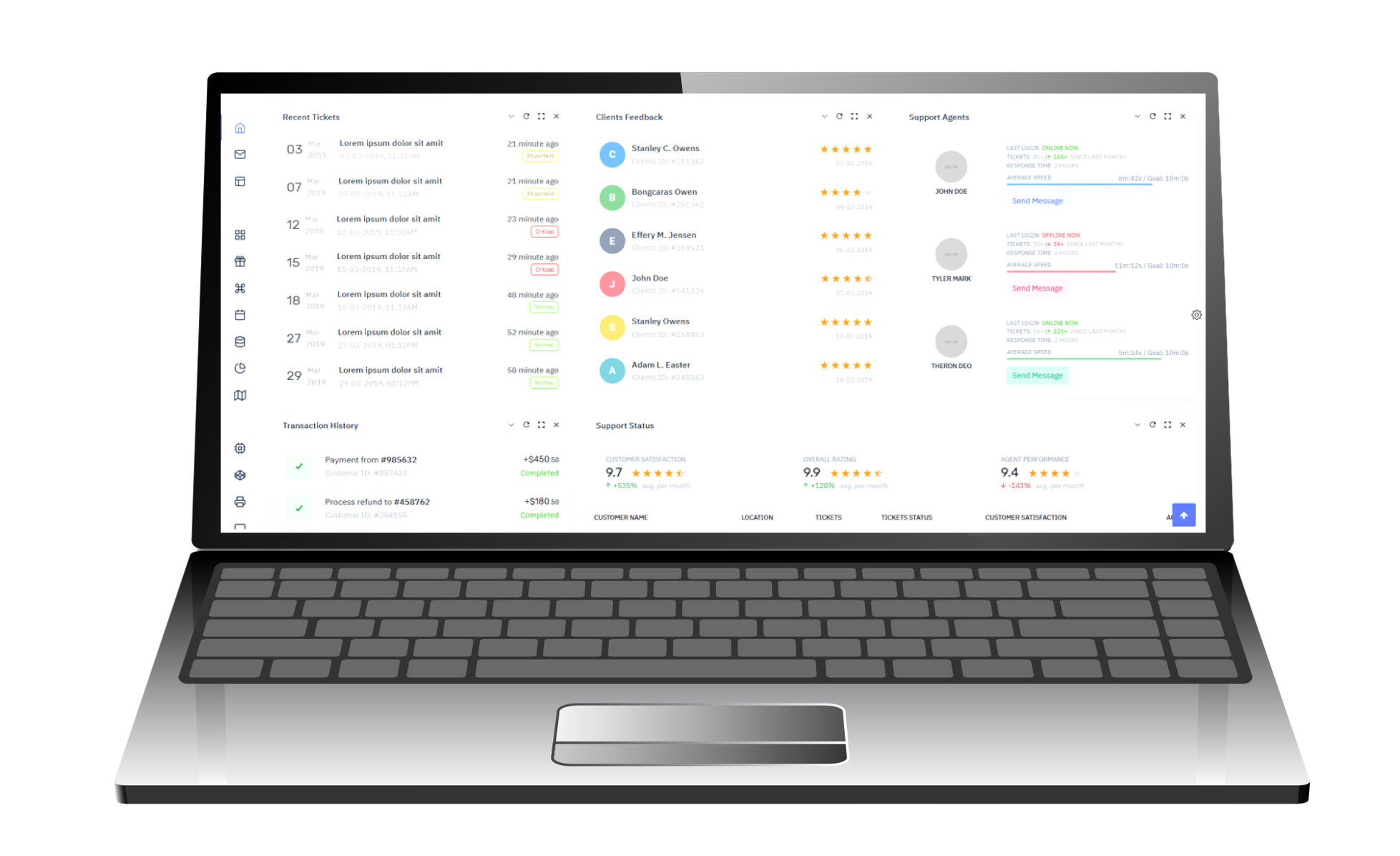

Detect Exceptions Pro-actively

Detect module enables planner to exactly see:

- Which Product SKU is at problem?

- Which all Locations causing problems for the SKU?

- When this problem is going to impact your supply chain?

- How big is the problem for the given SKU x Location?

- Why there is a problem at this location for this SKU?

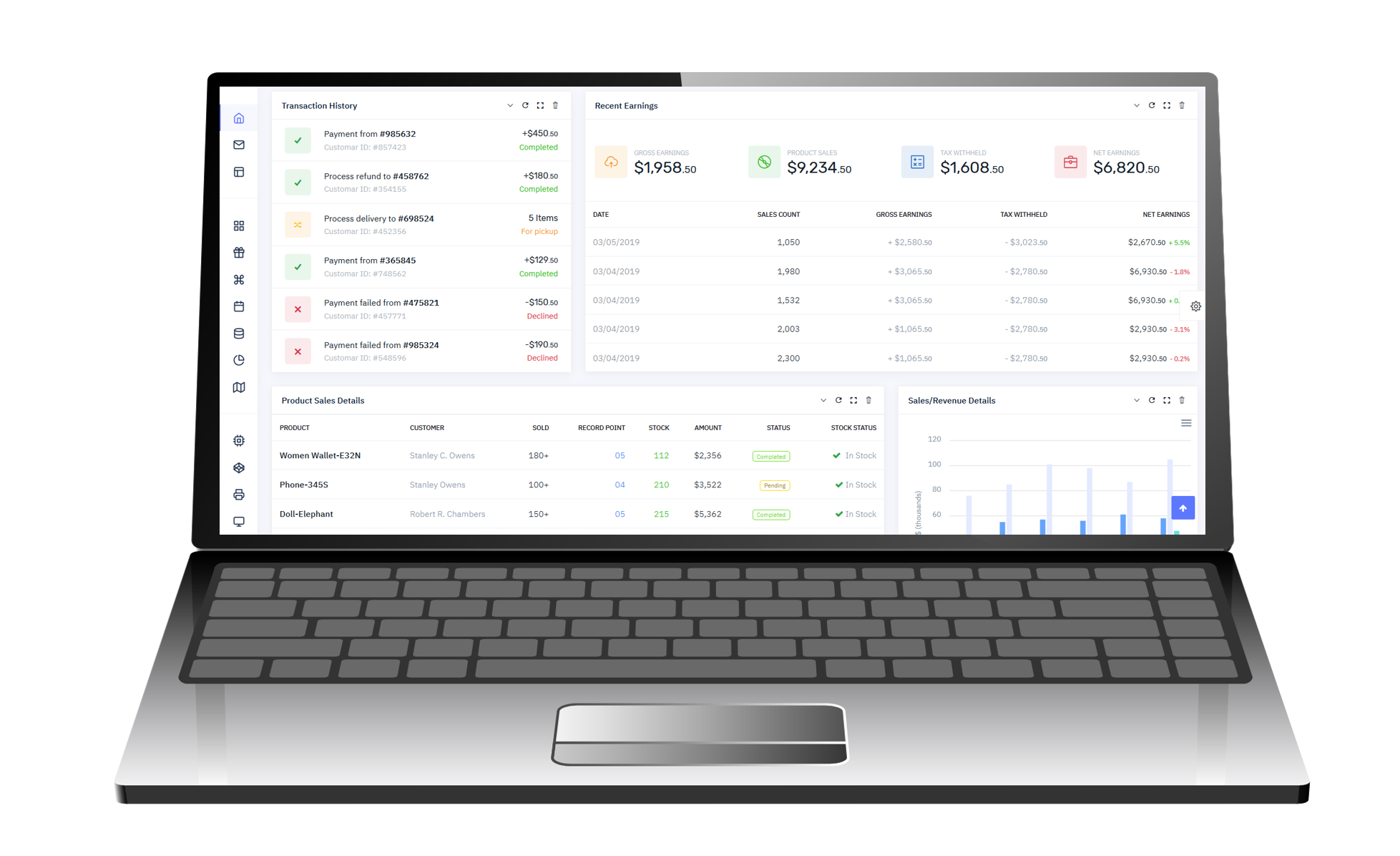

Diagnose for Causes

Diagnose module helps with the explain-ability by providing:

- A digital-twin of the supply chain for given Product

- Details of Problem & its root cause

- Causal Factors contributing to the root-cause

- Ability to simulate various actions & what-if analysis

- Get better understanding of various forces at play

Correct through Actions

Correct module empowers planner to:

- Work on mechanisms to mitigate exceptions

- Accept system generated Recommendations for actions

- Generate custom actions to mitigate exceptions

- Collaborate with other planners

- Define strategies to prevent risk from appearing again

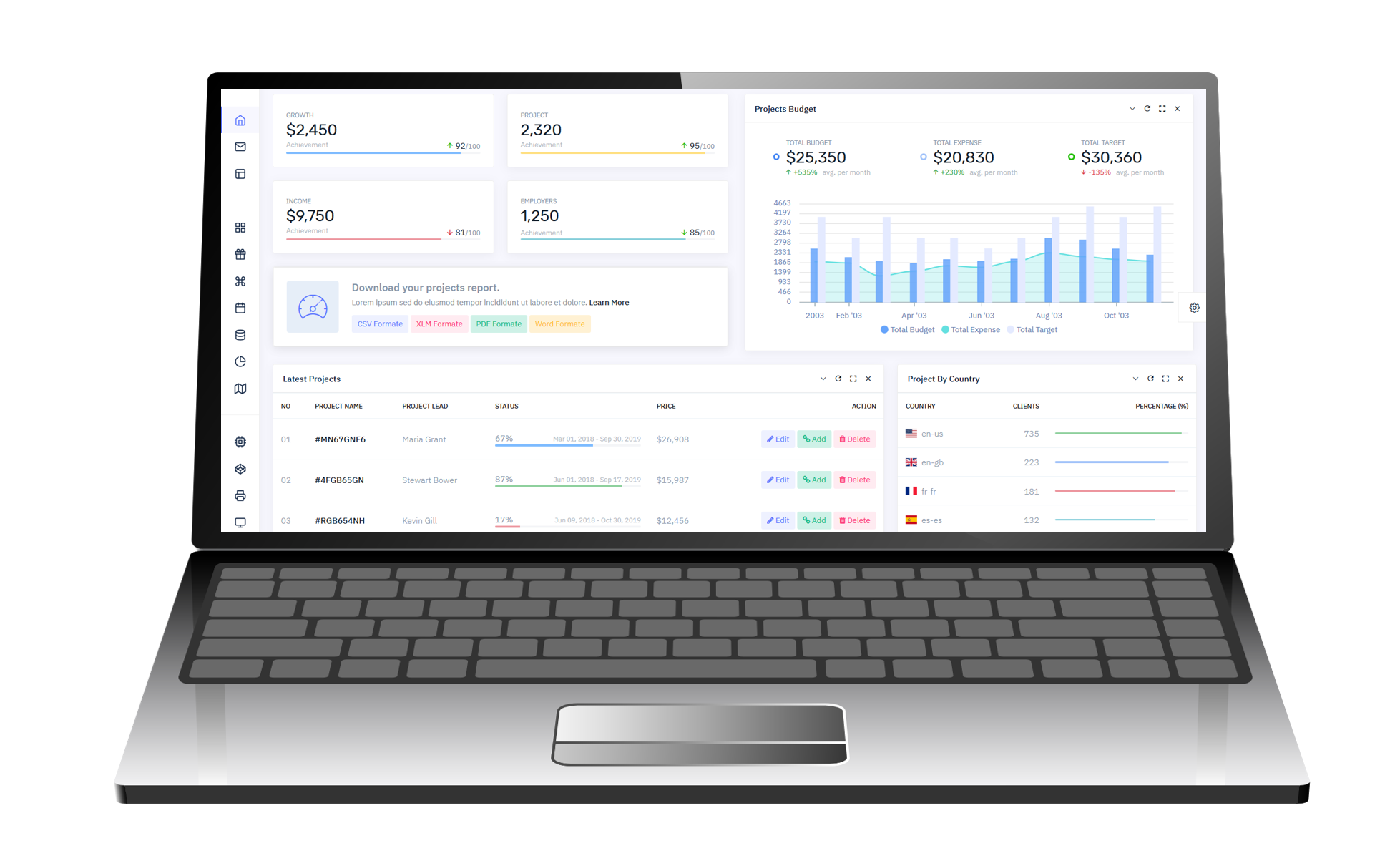

Commit to your System of Execution

Commit module facilities:

- Integration & Automation capabilities

- Planners can push mitigation actions to underlying ERP or System of execution

- Visibility into what got executed & what is pending.

- Value attribution to actions & value tracking

Let Us Connect !

One of our Demo Engineer will contact to introduce you to SCAI's Touchless-AI Platform for Supply Chain Optimization.